CNC Slitting Blade China: An In-Depth Guide

In the fast-paced world of manufacturing and industrial applications, quality tools are essential for achieving high efficiency and productivity. CNC slitting blades are among the most critical tools employed across various sectors, particularly in China, which is recognized as a global leader in manufacturing. This article will provide a comprehensive overview of CNC slitting blades in China, encompassing their benefits, manufacturing techniques, applications, and essential factors to consider when sourcing these vital tools.

What is a CNC Slitting Blade?

A CNC slitting blade is a cutting tool specifically designed for slitting applications. These blades are engineered to cut through various materials, such as metal, cardboard, plastic, and paper, with precision and efficiency. Using Computer Numerical Control (CNC) technology, these blades can perform intricate cuts required for high-accuracy applications.

The Importance of CNC Slitting Blades in Manufacturing

Manufacturing companies, particularly in sectors like packaging, textiles, and metalworking, rely heavily on CNC slitting blades. Here are some reasons why these blades are critically important:

- Precision Cutting: CNC technology ensures that the blades can achieve extremely precise cuts, which is vital for high-quality production standards.

- Increased Efficiency: High-speed CNC slitting blades can operate at significantly faster rates than manual cutting tools, leading to improved productivity.

- Versatility: These blades can be customized for a variety of materials and cutting processes, making them adaptable to different industrial needs.

- Durability: Made from high-quality materials, CNC slitting blades are designed for longevity, reducing the frequency of replacements and maintenance costs.

Manufacturing Processes of CNC Slitting Blades in China

The manufacturing process of CNC slitting blades in China involves several stages, each crucial to ensuring the quality and effectiveness of the final product. Here’s a detailed look into the manufacturing processes:

1. Material Selection

Choosing the right material is the first step in producing high-quality CNC slitting blades. Common materials include:

- High-speed steel (HSS): Known for its excellent wear resistance and toughness.

- Carbide: Offers superior hardness and strength, making it suitable for high-volume cutting applications.

- Stainless steel: Provides corrosion resistance, ideal for environments where moisture is present.

2. Blade Design

After selecting the material, CAD software is used to create detailed designs for the blades. This step is essential for ensuring precise dimensions and geometries that meet specific cutting requirements.

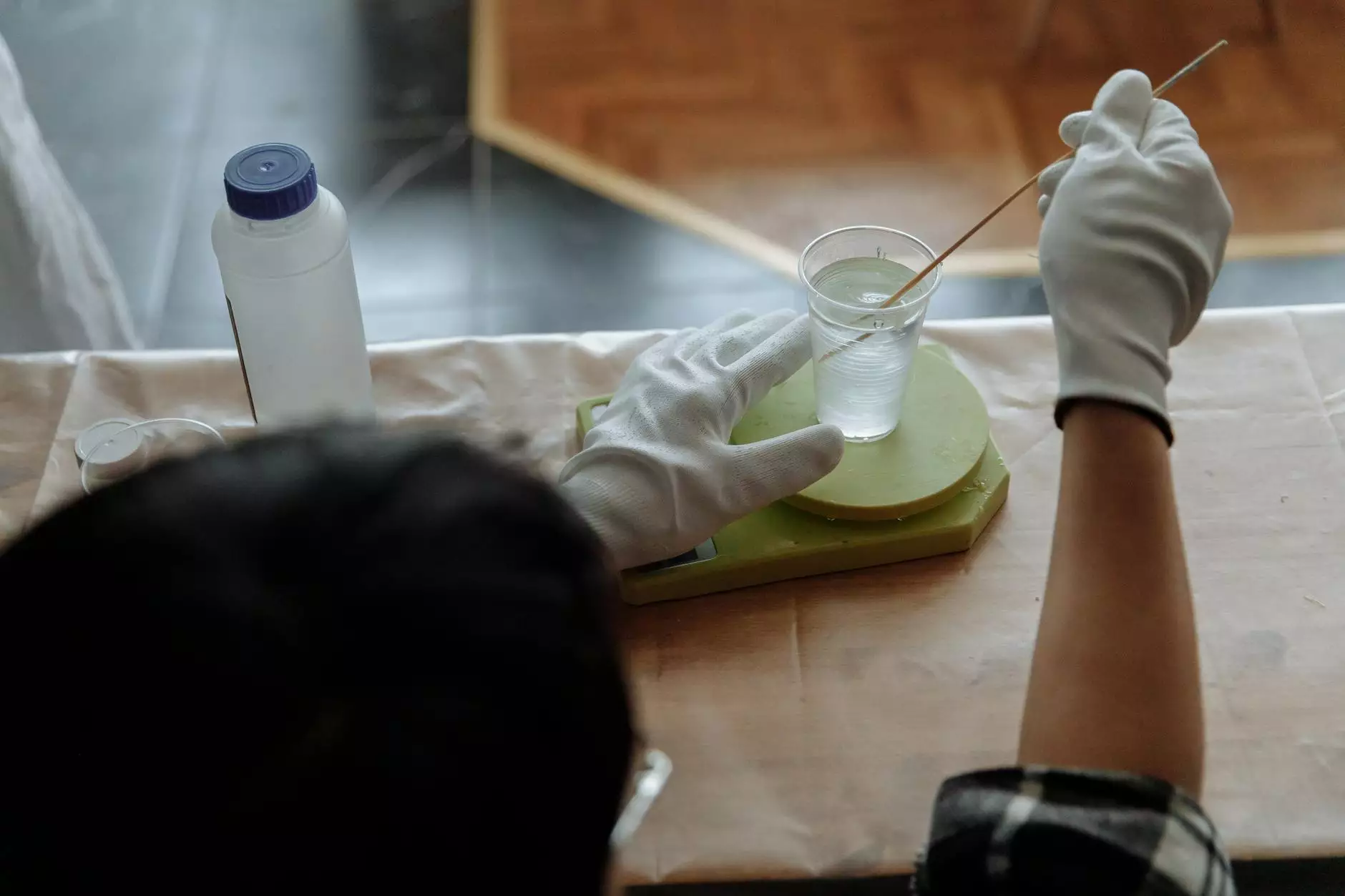

3. CNC Machining

The design is then translated into reality using CNC machining technology. The blades are cut, shaped, and refined to their final form with extreme accuracy. The CNC process allows for repetitive precision, ensuring each blade produced is identical.

4. Heat Treatment

To enhance the strength and durability of the blades, a heat treatment process is often applied. This process increases the hardness of the blades and improves their wear resistance.

5. Finishing

The final step involves polishing and coating the blades to reduce friction during operation and enhance their cutting performance. Techniques such as Teflon coating or titanium nitride (TiN) coating are commonly employed to improve their lifespan.

Applications of CNC Slitting Blades

The versatility of CNC slitting blades allows them to be used across various industries. Here are some key applications:

- Metal Fabrication: Used for slitting various metals into strips or sheets as part of the production process.

- Packaging Industry: Essential for cutting cardboard and flexible packaging materials into precise sizes.

- Textile Industry: Employed for slitting and cutting fabric in garment manufacturing.

- Paper Industry: Utilized for producing different paper grades by slitting rolls into specific measurements.

Benefits of Sourcing CNC Slitting Blades from China

Choosing to purchase CNC slitting blades from China can offer numerous advantages for businesses worldwide:

1. Cost-Effectiveness

China is known for its competitive pricing in manufacturing. This cost-effectiveness allows businesses to acquire high-quality tools without exceeding their budgets.

2. Wide Range of Options

With numerous manufacturers, China provides a vast selection of CNC slitting blades tailored to diverse requirements. Companies can select from various materials, designs, and specifications.

3. Strong Supply Chain

The established manufacturing infrastructure in China creates a robust supply chain, minimizing lead times and ensuring prompt deliveries, which is crucial for maintaining production schedules.

4. Innovation and Technology

Chinese manufacturers are increasingly adopting advanced technologies and innovative techniques, ensuring that the CNC slitting blades are at the forefront of modern cutting solutions.

Factors to Consider When Purchasing CNC Slitting Blades

When sourcing CNC slitting blades, especially from China, it is important to take several factors into account:

1. Quality Assurance

Ensure that the manufacturer adheres to strict quality control processes and certifications, like ISO standards, to guarantee the products meet international quality benchmarks.

2. Customization Options

Determine if the manufacturer offers customization to cater to your specific cutting requirements. This includes dimensions, blade design, and materials.

3. After-Sales Support

Robust customer support is essential. Verify what kind of after-sales service is available, including warranty and technical assistance.

4. Shipping and Logistics

Understand the shipping logistics offered by the supplier, including costs, timeframes, and handling processes to ensure timely delivery of the blades.

5. Reviews and Reputation

Research the manufacturer’s reputation through customer reviews and industry references. A reputable supplier can save you time and money in the long run.

Conclusion

In conclusion, CNC slitting blades from China represent a highly efficient, durable, and cost-effective solution for various industrial applications. By understanding the manufacturing processes, benefits, and factors to consider, businesses can make informed decisions when sourcing these essential tools. Whether you are in the metal fabrication, packaging, textile, or paper industry, investing in high-quality CNC slitting blades is crucial for enhancing your operational efficiency and product quality. By carefully choosing manufacturers like those found on szblade.com, you can ensure you acquire the best tools available for your cutting needs.

cnc slitting blade china